A new way to extract lithium for electric cars has been discovered by scientists in China

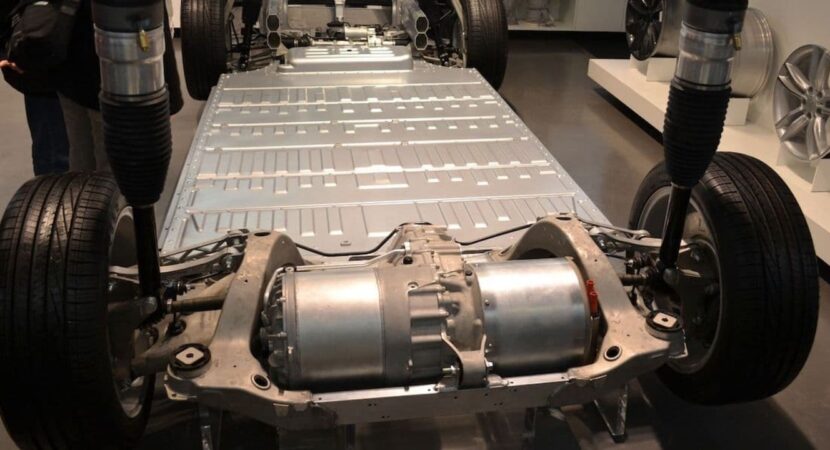

Researchers in China have discovered that there is a new way to extract lithium from used lithium iron phosphate batteries and are already thinking about using it in electric cars. This process, already considered innovative, generates Li 3 PO 4, which can be sold with considerable income to battery manufacturers.

Read also

Tsinghua University, located in Beijing reports that mechanical-chemical oxidation in solid phase, can offer a rapid extraction of about 99,7% of the lithium from cathode materials existing in lithium iron phosphate batteries (LiFePO4). This type of technology is one of the main methods of producing nanomaterials.

China: The advantages of using this method for lithium extraction

The main advantage of this method is that the extracted material is completely acid-free, in addition to the fact that the process can be completed in a shorter time of only about five minutes. During the extraction process, there is also no production of waste water. Still related to the extraction process, three new chemical products are generated, something that can generate a great financial incentive, also being significant for the process of recycling car batteries.

China studies process, researches and news in the electric car market

Some studies carried out recently, part of them by researcher Kang Liu, have shown the various benefits that lithium batteries offer, being a reliable alternative to nickel and cobalt base, which extends the range of electric vehicles by thermal modulation. However, unfortunately, the recycling solutions that currently exist in this area are still very limited, not being sustainable enough.

“For example, pyrometallurgy can require a high reaction temperature and involves high energy consumption and flue gas release”

“Hydrometallurgy requires acid-base reagents and can produce wastewater containing heavy metals. Research in bio-metallurgy is still in the scientific research stage.”, reports by researcher Kang.

Air Force F-16 fighters…

True friend, what they shot down were…

Air Force F-16 fighters…

I would like to know what planet you live on…

Air Force F-16 fighters…

Which genocide are you talking about? Than…

Air Force F-16 fighters…

Everything is fine, 100-year secrecy,…

Air Force F-16 fighters…

Well... It's flying scrap... Typical...

Is this really true?

Only if it's R$43 thousand inside the factory...

True, the sloop has to be fitted with a spring…

Brazil’s big problem is that…

What would be the cost of this engine?

I saw him there in Moscow at…

You won’t leave here for less than…

Planting trees is more efficient, and it doesn’t cost…