Hydrotreated vegetable oil (HVO) has been touted around the world over the last 12 months, with everyone wanting to know more about this new renewable diesel that pollutes less than petroleum products, being able to reduce carbon emissions and help companies to improve their environmental impact, without neglecting combustion engines

HVO is a renewable drop in the diesel replacement fuel. that offers users a 90% reduction in greenhouse gas emissions, as well as significant air quality benefits. Its renewable status is given due to the nature of its raw materials. which are usually plant, food or animal waste. In addition to all these advantages, HVO reduces fine particulate matter (PM) by 33%, hydrocarbons (HC) by 30%, carbon monoxide (CO) by 24% and nitrogen oxides (NO) by 9% . All pollutants with high emission levels when biodiesel is consumed.

HVO gains popularity and researcher highlights benefits

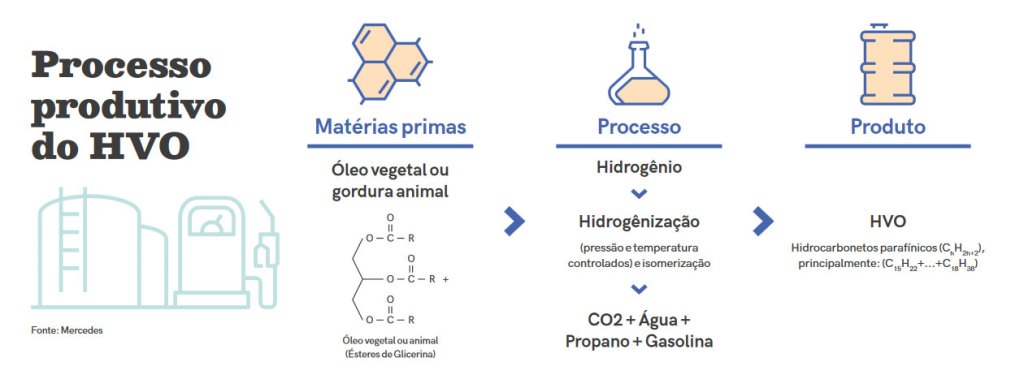

Renewable diesel (HVO) is created through a hydrogenation process, which simply means that it is created using hydrogen instead of methanol as its “catalyst” and that oxygen is removed from the vegetable oils in the process.

The HVO is a biofuel second generation, 100% made from residual raw materials, which undergo a much more complex refining process that produces a better quality and cleaner fuel, fully interchangeable with diesel.

It's a true turnkey diesel replacement, meaning users don't have to make upfront infrastructure changes or spend significant money on retrofits to ensure compatibility.

In short, it is a renewable fuel, capable of almost zero CO2 emissions when consumed, and during its life cycle has an emission of 50% to 90% less GHG compared to common diesel. In addition to reducing fine particulate matter (PM) by 33%, hydrocarbons (HC) by 30%, carbon monoxide (CO) by 24% and nitrogen oxides (NO) by 9% – pollutants whose emission levels are increased when using biodiesel.

Used pure or mixed with petroleum diesel in high proportions, green diesel is as efficient as fossil diesel, ideal for use in modern engines without the need for adaptation. In addition, for the production of HVO, it is possible to use the infrastructure of existing oil refineries.

HVO is not a new product

Some may not have heard of HVO in recent years, but it's not a new product by any means. It has been used in commercial fuels for over a decade across Europe, and in many Scandinavian countries it is available at the pump as regular diesel for consumer use. However, in the UK the product is finding new formulas and getting noticed, growing significantly in popularity over the past 12 months.

Companies are now realizing that they need to do something different when it comes to dedicated petroleum fuels and that, although HVO is not a 'cheap' option compared to diesel, it is the most viable and easy-to-implement solution at the moment, reaching a 90% reduction in the impact on the CO2 footprint. Compared to other clean energy alternatives of the future, such as electricity and hydrogen, it may also be the most cost-effective.

HVO is a fuel that, like biodiesel, can be produced from vegetable oils, such as palm oil, soy oil, sunflower oil, high oil (from wood chips), residual fats (cooking oil) and fats animals. But to specifically produce HVO, oils must come into contact with hydrogen under high pressure, and only then is fuel created. This process makes it possible to obtain it from a greater variety of raw materials that do not compete with food production.

Advantages of HVO over biodiesel

We separate some of the main advantages of HVO, highlighted by researcher Rogelio Sotelo-Boyás, from the National Polytechnic Institute of Mexico, in relation to the common diesel used in Brazilian territory. Check out:

- HVO is compatible with all current existing modern engines;

- The diesel of the future has greater flexibility in obtaining raw materials;

- Much more oxidation stability;

- Higher cetane percentage;

- It is 90% renewable and does not pollute the environment;

- HVO does not need water in its production process;

- It does not need any type of initial treatment to be marketed;

- It performs better in colder weather and regions with dense climates;

- Its transport does not cause any additional pollution.

As a rule, biodiesel is all fuel derived from renewable biomass, and HVO is also produced from the same raw materials. However, these products have different components, since, from a chemical point of view, HVO is a mixture of hydrocarbons (made up of carbon and hydrogen), while biodiesel is a mixture of esters (made up of carbon, hydrogen and oxygen ).

HVO is under discussion in Brazil and may arrive soon

Combustion engines present in Brazil that meet the standards established by the norms of the Proconve 3, which run on B-10 diesel, do not require any changes to use HVO. The only change needed would be a lubrication additive, as renewable diesel HVO has a low lubricity content.

Brazil, however, is still starting discussions regarding the application of HVO in the national territory. Currently, this alternative is already available for vehicles in Europe, Asia and North America. An industrial installation for the production of HVO is in the process of being set up in Paraguay, which opens up a horizon for the fuel in South America.

For the time being, in Brazil, the fuel is only produced in experimental character by Petrobras, without any regulation. However, a regulation proposal is already being processed by the National Petroleum, Natural Gas and Biofuels Agency (ANP). Perhaps, soon, we will have this green fuel option for our vehicles.

Air Force F-16 fighters…

True friend, what they shot down were…

Air Force F-16 fighters…

Well... It's flying scrap... Typical...

Air Force F-16 fighters…

I would like to know what planet you live on…

They discover the third largest deposit…

That’s why all foreigners and NGOs…

Air Force F-16 fighters…

Which genocide are you talking about? Than…

Do you speak any of the current languages of…

Several points to be analyzed: Matters…

I have one, the one on the road and one…

You must start thinking about Putin or…

Lol hamasete lol

I agree with you and much more, the…

He likes talking about his ass so much that…

I heard that the basic would be 130k…