Niobium, the wildcard of the industry of the future and abundant in Brazil, becomes the solution for electric cars and, together with graphene, will revolutionize the fate of technology

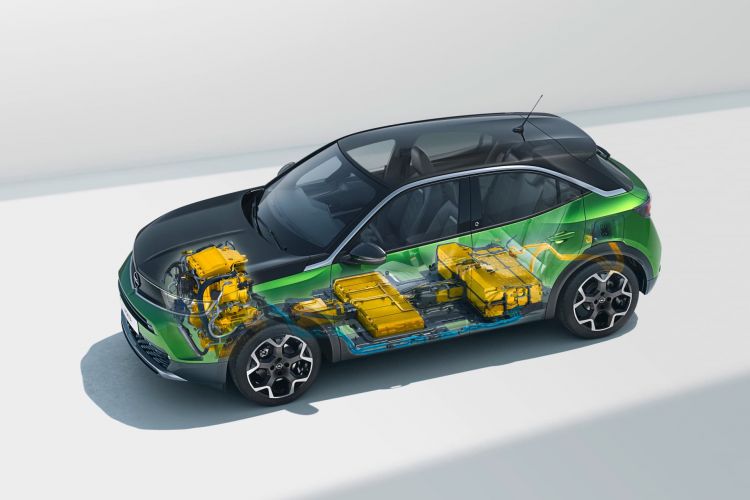

A fundamental component in electric cars and, therefore, the most expensive of all, batteries are responsible for marking the autonomy of these models, but they are not perfect: their capacity is decreasing over time, shortening their useful life and niobium, a material so abundant in Brazil, which together with graphene promises to revolutionize the destiny of humanity, would not lose its position of protagonist and becomes the solution in place of lithium to conserve the capacity of the batteries used by electric cars.

Read also

- Niobium, the “joker” for the industry of the future, with lighter cars, lower consumption in combustion engines and ultra-fast charging in electric cars. All this is possible with the presence of this metal so abundant in Brazil

- Brazil will be the protagonist of the niobium revolution in the world, the essential metal for the steel industry, electric cars, infrastructure, technology and health

- The world leader in niobium production CBMM enters into an international partnership and adopts Canadian technology to increase the performance of batteries in electric vehicles

- Discover the third largest deposit of niobium in the world

Electric car batteries (as well as those of any electronic device) lose some of their energy capacity before we do the first recharge. As Oak Ridge National Laboratory explains, the reasons for this are found in the degradation suffered by its chemistry and in the impurities that are created in the first charge and discharge cycle. Check out the video below.

Understand the composition of lithium batteries

To solve this drawback, Stanley Whittingham set to work. This is the chemist who invented lithium batteries in the late 70s: an achievement for which he was awarded the Nobel Prize in his specialty in 2019. Now he has led a group of researchers, who have found a way to stop this degradation that affects the capacity of electric car batteries, and therefore their useful life: a coating that protects the cells from this loss.

Before explaining his discovery, it is necessary to understand, at least, the composition of lithium batteries. These have cathodes made with alternating layers of lithium and oxide materials that are rich in nickel. This metal is used because it generates greater energy density and greater storage capacity… at a lower price, as it is cheaper than other materials.

However, not all are advantages: nickel in cathodes is unstable. This causes it to react easily, generating a series of impurities that cover the surface of the cathode and reduce the storage capacity by 10-18%… in the first cycle of charging and discharging the battery. It's not the only thing contributing to this decline: nickel can also generate instability within the cathode structure, something that decreases capacity over long periods of charge and discharge.

Increased capacity thanks to niobium oxide

Stanley Whittingham came across this scenario and has been working on it with a series of diffraction studies performed with X-rays and neutrons. This has been the starting point for arriving at an experimental chemical treatment in which the cathodes forget lithium to use niobium oxide.

The atoms of this chemical element have the ability to stabilize the surface and, consequently, reduce the losses that occur from the first cycle. Something they achieve as the temperature rises and drive the manganese atoms towards the cathode to improve their long-term holding capacity.

Translating this theory into practice and applying it to electric cars: by reducing first-cycle charging and discharging losses, the battery improves its long-term capacity, thus its service life.

Something that Stanley Whittingham and his team have already been able to verify, with this chemical treatment they managed to reduce the loss of capacity during the first charge and discharge cycle, which translates into better battery performance in the long term. At the laboratory level, and after 250 charge and discharge cycles, capacity retention was 93,2%.

Now, thanks to this breakthrough, they want to develop state-of-the-art lithium metal battery cells that deliver up to 500 Wh per kilogram, instead of the 220 Wh we have on average today.

With the development of these cells, the useful life of the batteries included in electric vehicles could be extended to make them, from the first charge, much more durable.

Brazil gains the first and largest graphene production plant in South America, capable of producing up to 5000 kg per year, which together with niobium will revolutionize the destiny of humanity

Brazil has 1/3 of the reserves of graphite (or graphite) and approximately 97% of niobium, which, when combined with graphene, will revolutionize the destiny of humanity. The inauguration of the first and largest graphene production factory on an industrial scale in South America, which took place on July 09, was attended by the President of the Republic, Jair Bolsonaro, the Chief Minister of the Civil House, Luiz Eduardo Ramos, and the Minister of Science, Technology and Innovation, Marcos Pontes. The unit will have the capacity to produce up to five thousand kilograms of high quality per year.

In his speech, President Jair Bolsonaro highlighted Brazil's potential: “We have a blessed homeland. Returning to the periodic table, we have all of it here in Brazil. Even in what is rare. We have around 1/3 of the graphite reserves, or graphite, in several states. We have approximately 97% of niobium, which, when married to graphene, will really revolutionize the destiny of humanity”, he said.

about graphene

Graphene is a material recognized worldwide for its incredible physical properties, such as high mechanical strength, lightness, malleability and high thermal and electrical conductivity. Brazil is the third largest supplier of the mineral graphite in the world and has the second largest world reserve of this material, which is the main raw material for Graphene. It is estimated that this market will move, in 5 years, more than 3 billion dollars.

Among the products that use this raw material are bulletproof vests, anticorrosive, self-cleaning and antibacterial paints, fabrics, motorcycle helmets, rebar for civil construction, batteries, among others.

A Civil House accompanies the policies for advanced materials to promote the harmonization and regulation of this topic with the various sectoral actions carried out by the other ministries.

Air Force F-16 fighters…

True friend, what they shot down were…

Air Force F-16 fighters…

I would like to know what planet you live on…

Air Force F-16 fighters…

Everything is fine, 100-year secrecy,…

Air Force F-16 fighters…

Well... It's flying scrap... Typical...

Air Force F-16 fighters…

Which genocide are you talking about? Than…

If no Federal money comes in, the risk…

I find it easier to "stock up on wind"...

Interesting !

I'm a bricklayer with vacancies in my area

Where is the place to register? No…

Wonderful project, it helps a lot of people.

I have a corolla xei 22/23 with 60…

I work in construction!