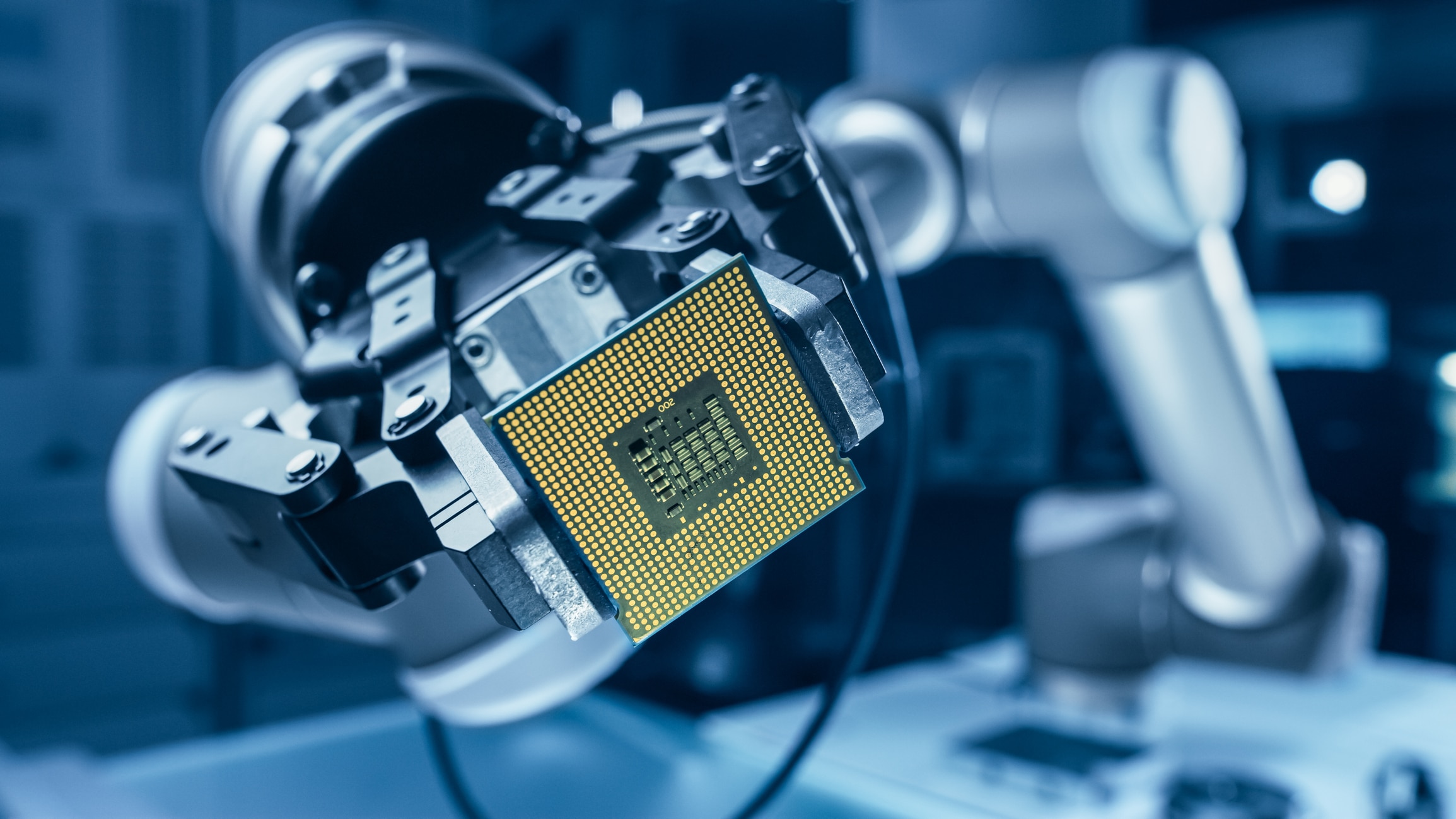

In addition to Intel, other companies are in the fight to see who expands their manufacturing units faster to help end the semiconductor crisis

Intel chose the American city of Ohio to install a new complex destined to manufacture semiconductors, which will have an investment of around US$ 20 billion, as a way to intensify and increase the production of computer chips in the United States, since users have been struggling with the shortage of these components for some time. Intel reported this Friday, 21, that the new complex, near Columbus, may initially have two factories to enact the end of the semiconductor crisis, offering about 3 thousand jobs, not to mention the additional jobs during construction and in companies close to the manufacturing unit.

Read also

Intel's billionaire investment to enact the end of the semiconductor crisis

Last year, when Patrick Gelsinger became Intel's chief executive, there was a rapid increase in the company's investment in manufacturing as a way to help reduce the United States' dependence on foreign chipmakers.

At the same time, Congress was under pressure to approve incentives aimed at increasing domestic chip production. These investments are expected to increase even more, as Intel has declared that it will invest US$ 100 billion – more than R$ 540 billion – over the next 10 years in its next manufacturing complex in the US.

According to Intel, just last Friday (21), US President Joe Biden met with Gelsinger at the White House to talk about the project.

New factories and start of production

Intel, headquartered in Silicon Valley (California), has factories in Oregon, New Mexico and Arizona. This will be the first time in over 40 years that Intel will build a new factory in a new state.

In March 2021, Gelsinger selected a complex near Phoenix for a $20 billion expansion, which is already underway. However, according to Intel, there is a lack of manpower, water and electricity to complete the complex, not to mention the lack of resources to manufacture semiconductors.

It is estimated that the complex in Ohio will be built later this year, with the first factory expected to start operating in 2025. The complex has enough area for up to 8 factories and related operations. With this, it is believed that it will help a lot in this semiconductor crisis phase.

Other companies are looking to expand their manufacturing facilities to compete with Intel.

In the US, Intel is not the only company expanding its production. Taiwan Semiconductor Manufacturing Company (TSMC) began construction in 2021 on a complex valued at $12 billion, 80 km from Intel's factory in Phoenix.

Samsung Electronics called Taylor, in Texas, for a factory valued at US$ 17 billion, with construction forecast for 2022. Since the beginning of the semiconductor crisis, several companies have been making efforts to minimize the situation, but it is noticeable, in this moment, that companies entered a great war to see who collaborates more with the reduction or extinction of the crisis – in addition to the issue of company revenues.

Gelsinger's strategy is based on the bet that Intel can be the main rival of Taiwan Semiconductors and Samsung in the manufacture of semiconductor chips made to order for other companies. For much of its history, Intel only worked with the manufacture of microprocessors and other types of semiconductor chips.

I already have experience but...

I would like to have an opportunity to…

The truth is, after the year…

As the President of VOLKS said in a…

All Brazilian Niobium stolen like slag…

(These cables not only support the receivers…

...if the plates work...

Good news