Cellulose transport by MRS and Bracell at the Pederneiras Intermodal Terminal has been so efficient that the numbers are impressive

With less than 8 months of operation, the Pederneiras Intermodal Terminal has already received the transport of 1 million tons of pulp to the Port of Santos, in the last week of April, by large companies MRS and Bracell. This points to the great efficiency in transportation and operations involved in paper production in Brazil.

MRS signed a contract with Bracell in July 2020 and built a large terminal specializing in pulp transport from scratch for 7 months, buying wagons and locomotives. Operations started in September 2021 and, after 8 months of operation, they have already reached the memorable mark of 1 million tons.

Understand a little more about how pulp is manufactured from eucalyptus in the video below

The solid results are cause for celebration, as cellulose is an essential product for the national economy

Achieving this result required a joint effort by engineering and project professionals, institutional relations and supplies, in addition to a quality infrastructure that would guarantee proper functioning. Strategic planning, set up by the large companies Bracell and MRS, was largely responsible for the success of this endeavor. After all, they managed to optimize the construction process, pulp production and, finally, transportation. The result could not have been otherwise.

Companies celebrate this great national feat as it points to a logistics quality comparable to that of first world countries. In this sense, the terminal contributes to a sustainable production chain and an exemplary pulp production and transport model.

A survey carried out by Jornal O Globo, with 135 publicly traded companies, showed that companies focused on the pulp and paper production sector are the ones that most focus on the sustainability agenda. In this way, it is a sector that is in constant alignment with the ESG policy (Environmental, Social & Governance), based on the environmental, social and governance pillars. In this sense, the companies MRS and Bracell fit these parameters with great social and environmental responsibility.

Commitment to sustainability starts in production

According to data Overview of the Pulp and Paper Industry in Brazil and the World, made by the Ministry of Mines and Energy, in 2022, Brazil is the second largest pulp producer in the world, second only to the United States. This gives great importance to the country, which is responsible for 11,3% of all pulp produced in the world.

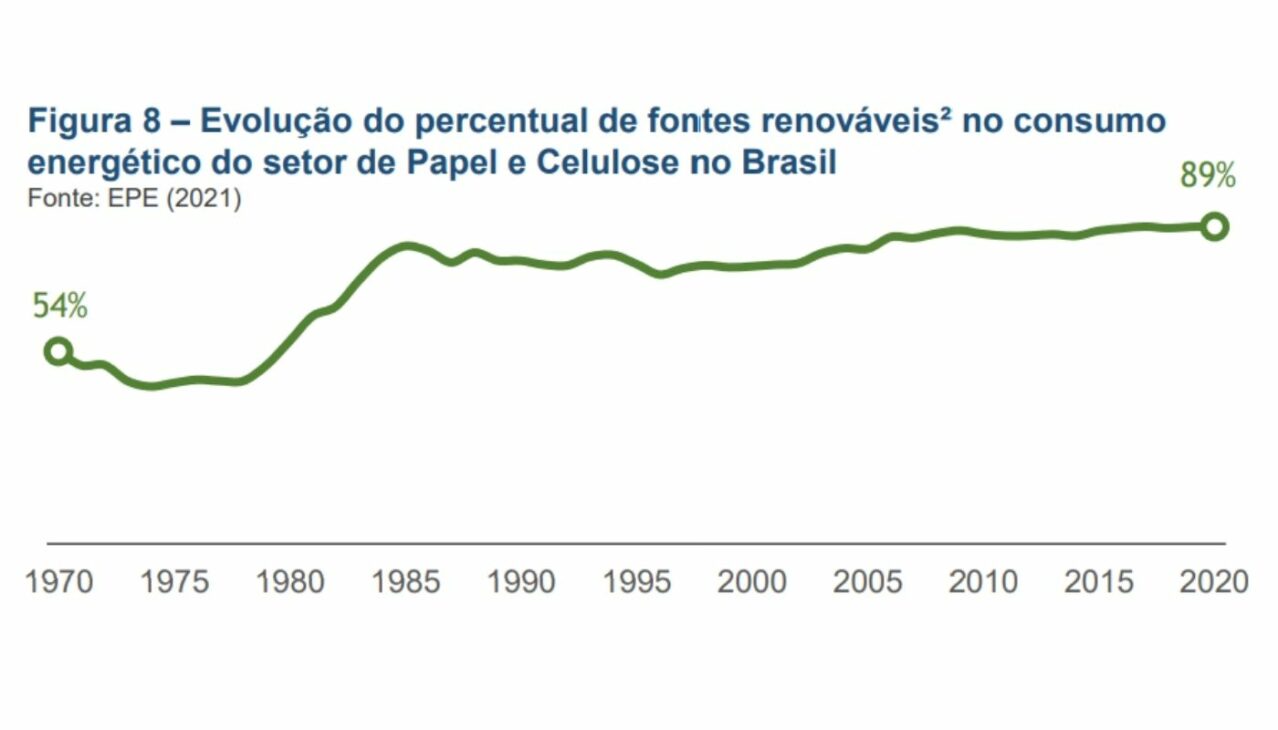

Therefore, the search for renewable resources to feed this industry segment has become a true mission, with which we are achieving success. The figure below shows the evolution in the percentage of use for renewable energy sources within the sector.

In addition to this significant evolution, it is worth mentioning that in Brazil, 100% of pulp production is obtained from reforested areas and 70% of this product is destined for export, mainly to the European Union. This contributes to sustainability from production to disposal.

In this sense, the large companies Bracell and MRS are contributing to the sustainable pulp chain, bringing greater technology and integration in favor of the environment. The milestone of 1 million tons transported demonstrates the efficiency of national cellulose and the heating up of the market for the coming years.

My watzp,62.9.8210.1837.

Hello good afternoon, my name is Joel Pereira, I’m at…

I had Monza 1994, Classic, very good,…

It's worth millions of dollars and explodes just like that...

Good afternoon! My dream is to be able to work in this…

Attention JAPANESE HONDA owner, from Honda, inspect…

This news is a joke, with so many things…

I want to have a monza again