At first, it is necessary to point out that, yes, recycling electric cars is more difficult than conventional cars. This is because ordinary scrap metal recycling is easy, and combustion cars have large steel bodies and aluminum transmission castings.

On the other hand, when we analyze the components and minerals in the engines, we realized that electric car batteries are more difficult to separate, delaying recycling. However, this process is not impossible. Incidentally, because they are extremely valuable, recycling electric cars ends up being very worthwhile.

At the same time, it is necessary to point out that the lithium extraction from the ground – for making electric cars – could suddenly end. However, closed-loop recycling is unlikely to end. In other words, even if it is more difficult, recycling electric cars should be an essential topic for automakers and those interested in the ecological situation of the planet.

So JB Straubel, who is famous for inventing the significant hardware of the Tesla, now owns his own company – Redwood Materials – to start recycling electric cars. In addition, other companies are already eyeing the segment to get ahead of the competition.

Northolt, one of the biggest suppliers of batteries for electric cars in Europe, is creating a recycling plant. On the other hand, Renault is turning Flins, a historic car manufacturing plant, into an electric car recycling conglomerate.

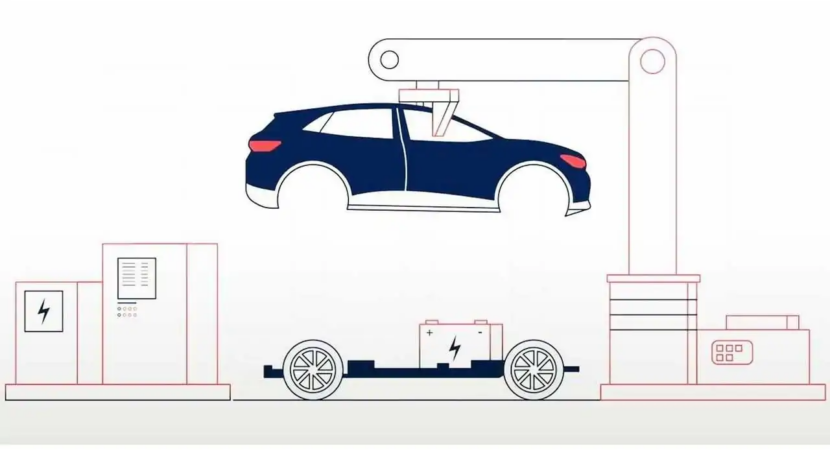

Slowly, recycling processes will improve. Currently, there are two systems for this: pyrometallurgy which, by using heat, consumes energy – which needs to be renewable. And we also have hydrometallurgy, which uses Chemicals, that is, it is necessary to clean the residues. In both cases, it is expected that the recycling of electric cars will be accelerated to combat ecological problems of their manufacture.

Electric car recycling is already a reality in Brazil

In recent months, B.MW Group Brazil, Metalúrgica Tupy and Senai Paraná entered into a partnership to create sustainable processes that guarantee the recovery of chemical compounds from electric car batteries.

With initial investments of R$3,4 million, each company will bring specific knowledge to studies within its area of expertise.

The mission of the partnership is to develop the recycling of lithium batteries by hydrometallurgy, being the most ecological process for recycling electric cars. In addition to emitting fewer greenhouse gases, it is also not heavily dependent on mineral extraction.

The initiative provides a new scenario for the use of recycled minerals in the manufacture of new batteries. Thus, dependence on primary mineral raw material is considerably reduced. With a duration of 2 years, it is expected that the first results will come out in the first quarter of this year.

Finally, the project's mission is to recycle electric car batteries, to ensure the resynthesis of the active material of a battery, to ensure 100% recycling. In addition, the entire process must be ecological, to ensure the sustainable potential of the initiative.