The union of niobium with diamond can be used in the renovation of road pavements, airport runways, modernization of metallurgical factories, nuclear power plants, bridges and other structures due to its high performance, durability and solidity.

New technology produced from diamond and niobium powder, with a high degree of hardness, resistance and non-toxic properties, is the novelty that promises more innovation and efficiency for civil construction and the oil industry in Brazil and in the world.

Read also

- Brazil gains the first and largest graphene production plant in South America, capable of producing up to 5000 kg per year, which together with niobium will revolutionize the destiny of humanity

- Graphene, the powerful flexible material 200 times stronger than steel and thinner than a strand of hair, is abundant in Brazil and will make the country a leader in the global technological revolution

- Partnership between the largest niobium producer on the planet CBMM and the Canadian multinational Nano One foresees new investments in lithium-ion batteries

- Brazil launches the first Niobium battery that, together with graphene, promises to revolutionize the world market for heavy loads

The innovative project, with a high degree of hardness, resistant and non-toxic, to be used in the oil industry and civil construction, was developed by the scholarship holder of the Coordination for the Improvement of Higher Education Personnel (CAPES) Meysam Mashhadikarimi, for his doctorate by the Program Graduate Program in Materials Science and Engineering at the Federal University of Rio Grande do Norte (UFRN).

The technology that promises to revolutionize civil and oil construction can be used in the renovation of road pavements, airport runways, modernization of metallurgical plants, nuclear power plants, bridges and other structures, due to its high performance, durability and solidity.

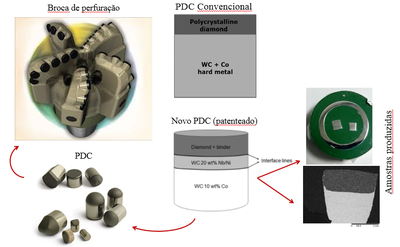

Mashhadikarimi explains that his research resulted in the creation of a composite product for making diamond tools, called condensed diamond body, which is the result of the combination of diamond dust and pure niobium.

With characteristics that show greater hardness, this combination results in a compound with less porosity and greater resistance to wear during use. To arrive at this result, it was necessary to look for a suitable binding element, which would prevent the diamond from losing its solidity and hardness, becoming more fragile. The studies showed that the use of pure niobium would be ideal for the performance of the compound.

The mixture of these two substances allows the new material to have unique and valuable characteristics for the civil construction sector. “The diamond body sintered with a pure niobium binder has an absence of porosity and greater hardness, factors that, together, result in greater resistance to wear”, he explains. The new technology can be used in the renovation of roads and airport runways, in the modernization of metallurgical plants, nuclear power plants, bridges and other structures, due to its characteristics.

“We replaced cobalt with niobium with the objective of reducing failures and increasing its useful life”, said the doctor in Science and Materials Engineering for UFRN, Meysam Mashhadikarimi. In addition, replacing conventional binding elements, such as iron and cobalt, with niobium, reduces the risk of contamination for workers when handling machines, since the material is non-toxic.

The work has already been patented and its industrial application recognized, providing more quality for the infrastructure in possible future projects.