Depending on the industrial sector in which it is necessary to use water in the process, there are 8 main treatment methods today combined with technology

Society has never valued water as much as in this prolonged drought. But many are unaware of the techniques involved in its treatment in the industrial context, in order to take advantage of every drop and return this precious resource back to the production chain.

Read also

- Millionaire project – Cosern, a Neoenergia company, opens a public call for energy efficiency projects for industrial areas, commerce and services, residential and government buildings

- With an increase of 118%, solar energy generation has 400 thousand consumers in Brazil, according to Absolar

- Brazilian oil company PetroRio, sells its entire stake in the Manati natural gas field, in Bahia

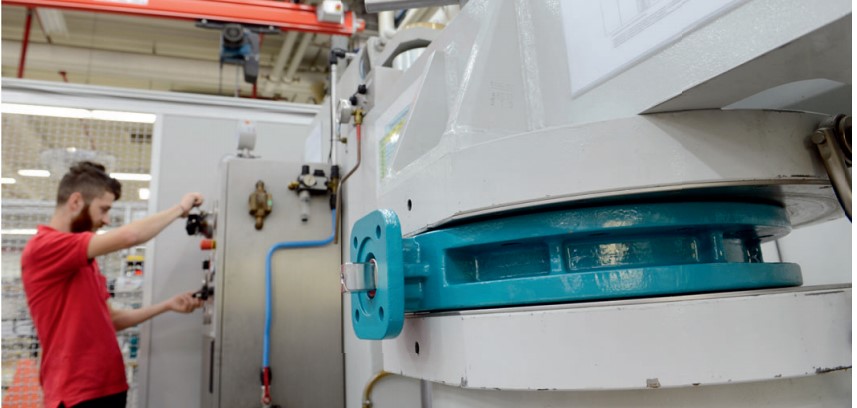

The fact is that each manufacturing unit requires different water applications, with very specific requirements, for example, in relation to the equipment that uses it for cooling or in the form of steam. They need to be very well defined to offer an adequate configuration and guarantee a correct choice, for example, of the system's valves, with customized dimensions suitable for the operating parameters (pressure, temperature and fluid).

From my experience with this equipment, I would like to highlight below the main water treatment situations allowed today by technology.

Potable water

Usually recovered from groundwater, it requires different actions to be effectively considered potable. The main measures include the precipitation or flocculation of suspended particles; absorption of dissolved organic substances with the use of activated carbon; ultrafiltration; sterilization with the addition of chlorine or through UV light radiation, among others. Below is a list of some of these cleaning techniques:

*Ultrafiltration

The water to be treated is conducted under reduced pressure (< 1 bar) through diaphragms with pores of approximately 0,01 μm. In addition to the retention of tiny solid substances, opacities, pollens and bacteria, and, partially, retention of viruses. Only water, soluble ingredients, such as hardeners or mineral substances, and smaller molecules pass through the diaphragm.

*Ion exchanger

In certain regions, groundwater may contain high concentrations of alkaline earth ions, various types of carbonic acid, and sulfates. For partial demineralization, drinking water passes through the ion exchanger's mixing bed, which reduces levels of nitrate, sulfate, chloride, hydrogen carbide (HCO3-) and calcium and magnesium hardeners. The carbonic acid, formed by the reaction of these products, can be removed in a purified water tower, connected downstream. In this case, butterfly valves are most suitable.

*Ultraviolet decontamination

Before reaching homes, the water can still undergo decontamination using UVC radiation, a physical process in which the microorganisms that are still present in the water are neutralized, which prevents their proliferation.

In addition to drinking water treatment, there are other water qualities to be treated in the context of industry:

industrial waste water

This is a very complex treatment, as each wastewater has its own characteristics, and the final product also has specific determinations. To customize the desired result, versatile valves and process controllers are needed that allow individual attention to the operating fluid and the entire process.

Processing water recovery

Whether to feed boilers for steam production, to cool power stations or as a basic liquid in the pharmaceutical industry, to be used in industry, water needs to be distributed, blocked and dosed. For this, rather complex multiway block valves or valves are used.

Purified and high purity water recovery

The purity of process fluids is decisive in many segments to obtain the proper quality of the final product. In the semiconductor industry, for example, preparing high purity water of the best quality is a competitive advantage. And in order for them to reach the required quality, the system components must also meet certain requirements. Here, I recommend using heavy-duty equipment made from fluoro plastics.

Desalination of sea water

Finally, this technique should meet a demand in the coming decades, and not only in industrial countries, due to the growing scarcity of water. One efficient method is the recovery of potable water through seawater desalination.

*Mateus Souza is general sales manager for the industrial area at GEMÜ Válvulas, Measurement and Control Systems for the Energy and Industry area.