Mahle, the company responsible for the project, developed the most durable electric motor in the world with continuous torque and capable of revolutionizing the automotive industry.

Engineers in Germany have developed what they claim is the world's most durable electric motor, built to be equipped in eletric cars of all sizes, from cars to even tractors. The electric motor can run indefinitely at its highest performance point.

Understand all the details of the world's most durable new engine with continuous torque

According to the company executive Mahle, Martin Berger, developing a large electric motor that delivers high performance in the short term is easy. What was still lacking in the electric vehicle market until now was the world's most durable engine, which is compact, making electric vehicles unrestricted for daily use.

The new SCT electric motor It is the solution to many problems. It is important to note that SCT stands for Superior Continuous Torque. Although very compact and lightweight, the world's most durable new engine continuously delivers 90% of its peak torque capacity.

This makes it possible for it to be used in electric vehicles of all types, each in its most demanding conditions. Classic examples are driving an electric truck over valleys and peaks in mountainous regions, and the multiple starts of an electric passenger car.

Electric powertrains for these current vehicles do not cover these scenarios as effectively. Mahle's new electric motor was developed to be particularly efficient within a certain range of revolutions (rpm). This innovation complements another technology introduced by the company in the last year, when it presented an engine that works much more efficiently in a wide range of rpm.

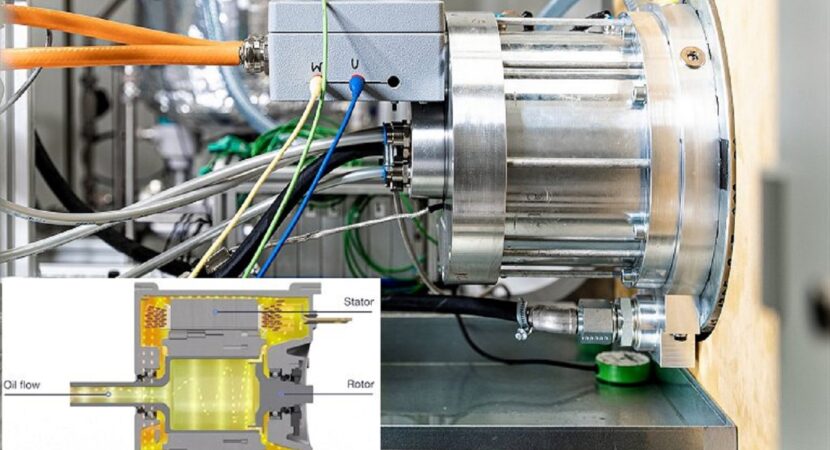

Mahle electric motor is oil-cooled

The electric motor's superior performance was achieved due to an innovative oil-cooling concept that not only makes the engine more powerful, but also allows the waste heat generated to be utilized throughout the vehicle's system.

Another gain is in the propeller design, which is completely compact, reducing material costs and the weight of the electric car. A lighter engine requires less material during its production, allowing the batteries to also extend their autonomy because the vehicle weighs much less, and expands the net charge of commercial vehicles.

In developing the world's most durable engine, the company opted for what is known as permanent excitation motor, which makes it possible to develop a much more compact motor that does not use the transfer of energy to the rotor as excitation current, making the electric motor much more efficient and wear-free.

To generate the motor's magnetic field, neodymium magnets were used, currently stronger permanent magnets produced on a large scale. However, with the company concerned about the supply of this material in rare earths, the propellant can also be developed without magnets, for this purpose including a non-contact transformer, resulting in a slightly larger motor.

Vitesco develops electric motor without magnets

In Oslo, a German company developed an electric drive motor Optimized for higher electric car ranges in the future.

The well-known externally excited synchronous electric machine does not require the use of rare earth metals and is specifically designed for higher ranges and faster driving, so future electric cars will have greater range.

In place of magnets, the rotor shown uses coils. In addition to the efficiency at high speeds, this has the advantage of avoiding the value of permanent magnets, which have already reached a maximum of 10 years.