Promising to be a possible and ideal substitute for petroleum-based materials, a new thermal insulation made of wood can be a solution for civil construction in an attempt to create more sustainable buildings.

A construction can now prepare itself to build buildings that are much more efficient in terms of energy and, also, more environmentally sustainable. Scientists are using a material that is thermally insulating and developed from wood, free of petroleum derivatives.

New thermal insulation made of wood, developed by scientists, can help civil construction in the elaboration of more sustainable buildings

Developed by scientists in Sweden, the new thermal insulator surprised with its performance, being as good as or much better than common thermal insulation materials, made with materials based on oil, such as, for example, expanded polystyrene.

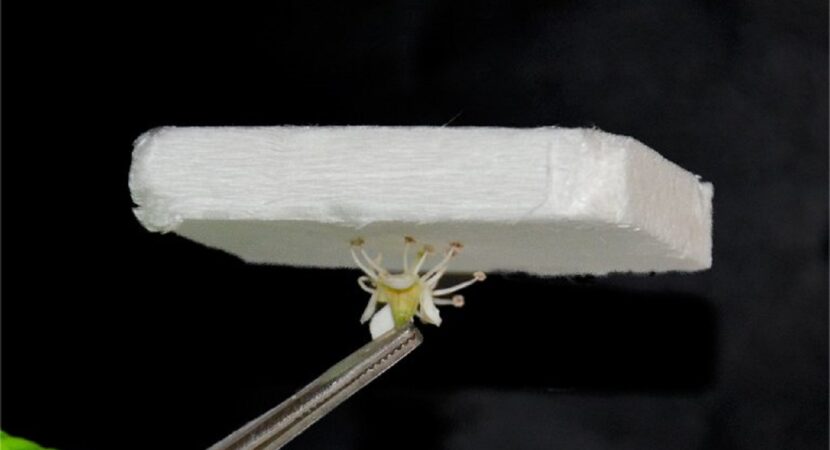

The thermal insulation developed by scientists in Sweden is made with wood integrated into an airgel. However, despite appearing new, the wood cellulose airgel is not really a novelty, as scientists have been advancing in research and development of new gels and other compounds for some time, performing various tests with various applications, including transparent wood, which has already become famous.

However, the team of scientists still does not guarantee that their new method can actually represent a breakthrough in the process of controlled creation of thermally insulating nanostructures in the pores of wood, for the time being, doing so without the need to add other substances.

Outperforming other petroleum-based materials, insulation made from wood and airgel could replace other less sustainable types of insulation

According to Professor Yuanyuan Li, from Royal Institute of Technology, strong bio-based aerogels could be used to replace current fossil-based aerogels, for super thermal insulation, something that could contribute to the energy efficiency, bioeconomy and mainly for the sustainable development of society in general.

In fact, civil construction may invest in these thermal insulators in the future, as a way of helping to form a sustainable society. Thermal insulation of buildings, due to energy savings with air conditioning, is not the only potential use for wood airgel, as its unique structure allows new, more advanced materials to be created for storage, energy conversion and even tissue engineering.

Professor Yuanyuan Li also gave the example of packaging, whose plastic foam, such as polystyrene, helps to prevent heat transfer between objects and the surrounding environment, as a way of keeping goods cool during transport/storage. However, the training , of nanofibril networks in the internal part of the empty spaces of the wood can result in a wood with high thermal insulation.

Thermal insulation manufacturing process

The process already begins with the delignification of the wood, that is, the removal of the lignin, which is the component that gives color and resistance to the wood, is carried out, leaving only the pores or cavities empty. The next step is to reduce the thermal conductivity of the material, invading the large empty pores to generate more nanopores inside them.

These nanoporous structures are only created when the cell walls are partially dissolved, followed by controlled precipitation. For this, a mixture of ionic liquid is made to partially dissolve the cell wall moments before adding water, causing networks of nanofibrils to be generated, making the cavity nanoporous.

Professor Li also claims that her team of scientists managed to achieve a high and significant level of control over the precipitation process, that is, they can create the precise level of nanoporosity so that the insulator can achieve optimal thermal conductivity.